Spot welds play a vital role in manufacturing by providing fast, reliable bonds between thin metal sheets. Using pressure and electrical current, you create localized, high-strength connections that are perfect for assembling complex structures efficiently. This process is indispensable in industries like automotive and manufacturing, enabling high-volume production with consistent quality. If you want to understand how these techniques guarantee durability and precision, continue exploring the key factors that influence weld quality.

Key Takeaways

- Spot welds create quick, strong metal bonds essential for efficient manufacturing processes.

- They enable high-speed assembly of complex structures with localized, reliable joints.

- Resistance spot welding uses electrical resistance to generate heat for melting and bonding metal surfaces.

- Proper control of surface cleanliness, pressure, and current ensures high-quality, durable welds.

- Widely used in automotive and industrial manufacturing to ensure secure, high-volume production.

Spot welds are essential in joining metal parts quickly and securely, especially in the automotive and manufacturing industries. These welds provide a reliable method for creating strong, localized bonds between thin metal sheets, enabling manufacturers to assemble complex structures efficiently. To achieve this, you need to understand the various welding techniques involved in spot welding and how they influence material bonding.

Spot welds ensure quick, secure, and localized metal bonding for efficient manufacturing.

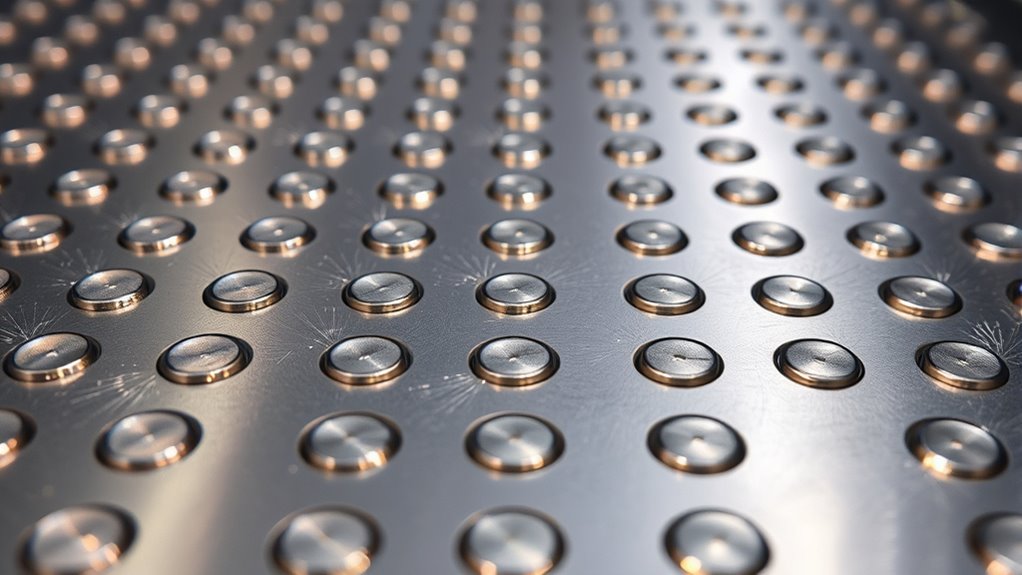

The core principle behind spot welding is applying pressure and electrical current to specific points on metal surfaces. When the current passes through the contact area, it generates heat due to electrical resistance, melting the metal at that precise spot. As the current stops and pressure remains, the molten metal cools and solidifies, forming a durable bond. This process is fast, making it ideal for high-volume production lines where speed and consistency are critical.

Different welding techniques can be employed to optimize material bonding depending on the type of metals you’re working with and the desired strength of the joint. Resistance spot welding is the most common, utilizing electrodes to clamp the parts together while passing current through them. Alternatively, you might use projection welding for joining thicker materials or when multiple welds are needed in close proximity. In some cases, you can combine spot welding with other techniques like laser or ultrasonic welding for specialized applications, especially when working with dissimilar metals or delicate components.

Material bonding through spot welding isn’t just about holding parts together temporarily; it creates a permanent, high-strength connection. The quality of this bond depends on several factors, including the surface cleanliness, the pressure applied, the current intensity, and the duration of the weld. Proper control over these parameters guarantees the weld penetrates deeply enough to establish a solid metallurgical connection, preventing issues like weak joints or failure under stress.

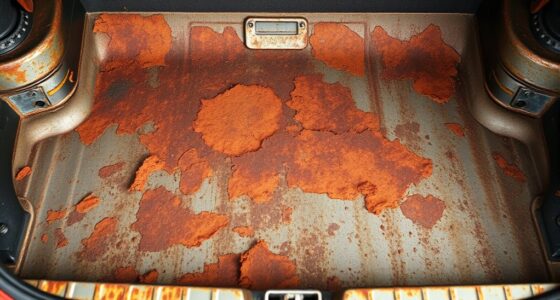

You should also consider the properties of the materials involved. For example, galvanized steel may require special techniques or additional surface preparation to avoid weld spatter or corrosion. Aluminum, with its high thermal conductivity, demands increased current or longer welding times to achieve a strong material bond. Adjusting welding parameters based on material types helps ensure the integrity of each weld and the overall durability of the assembly. Additionally, understanding the different animal species and their specific needs, such as sheep and goat co-habitation, can be crucial for maintaining healthy and productive farm animals.

Frequently Asked Questions

What Materials Are Best Suited for Spot Welding?

You should choose materials with good compatibility for spot welding, like mild steel, stainless steel, and aluminum. Make certain proper surface preparation, such as cleaning and removing any contaminants, to achieve strong welds. Materials that are too thick or have coatings like paint or rust can hinder the process. By selecting compatible materials and preparing surfaces well, you’ll get solid, reliable spot welds that last.

How Does Thickness Affect Spot Weld Strength?

Think of thickness as the armor of your materials; the thicker, the more challenging it is to achieve a strong weld. As you increase thickness, weld penetration becomes harder, risking insufficient fusion. This can lead to material deformation and weaker spots. To guarantee strength, you need to adjust your welding parameters, like current and time, so the weld bonds effectively without damaging the material.

Can Spot Welds Be Repaired Easily?

Yes, spot welds can be repaired easily if needed. During weld inspection, you’ll assess the spot weld durability and determine if it’s compromised. Repair involves removing the faulty weld and applying a new one, which is straightforward with proper equipment and technique. Ensuring good weld quality during initial work reduces the need for repairs. Regular inspections help catch issues early, maintaining the overall strength and safety of the assembly.

What Are Common Defects in Spot Welding?

You might encounter common defects like weld porosity and weld cracking in spot welding. Porosity occurs when trapped gas creates bubbles, weakening the weld, while cracking happens due to stress or improper technique, leading to fractures. These issues can compromise joint strength and durability. To prevent them, guarantee proper electrode condition, correct welding parameters, and clean surfaces. Regular inspection helps identify defects early, maintaining the integrity of your welds.

How Does Electrode Design Influence Weld Quality?

You’ll be surprised to learn that electrode design can improve weld quality by up to 30%. Choosing the right electrode material, like copper or tungsten, guarantees better conductivity and reduces wear. The electrode shape also matters—flat, pointed, or convex designs focus pressure and heat more effectively, leading to stronger, consistent welds. By optimizing these factors, you can markedly reduce defects and enhance overall weld performance.

Conclusion

So, next time you marvel at the seamless strength of a car’s body or a sturdy appliance, remember the humble spot weld. It’s funny how such tiny welds do so much heavy lifting, often unnoticed. Without them, those sleek surfaces might just fall apart. Ironically, it’s the simplest welds that hold complex structures together, proving that sometimes, it’s the smallest things that have the biggest impact. Who knew a tiny spot could be so powerful?