Rust starts when moisture and oxygen contact your metal surfaces, initiating a chemical process called oxidation that creates tiny iron oxide particles. If these particles aren’t protected, they spread, causing the rust to grow and flake off, exposing more metal underneath. Rust is encouraged by harsh environments and trapped moisture in crevices. To understand how you can prevent this damage and keep your metals strong, keep exploring these essential details.

Key Takeaways

- Rust begins when water reacts with iron or steel surfaces, initiating oxidation.

- Moisture and oxygen exposure accelerate rust development, especially in harsh environments.

- Rust spreads from small initial spots, flaking off and exposing fresh metal to further corrosion.

- Trapped moisture in crevices feeds ongoing oxidation, increasing rust growth and spread.

- Damage to protective coatings allows rust to expand rapidly across the metal surface.

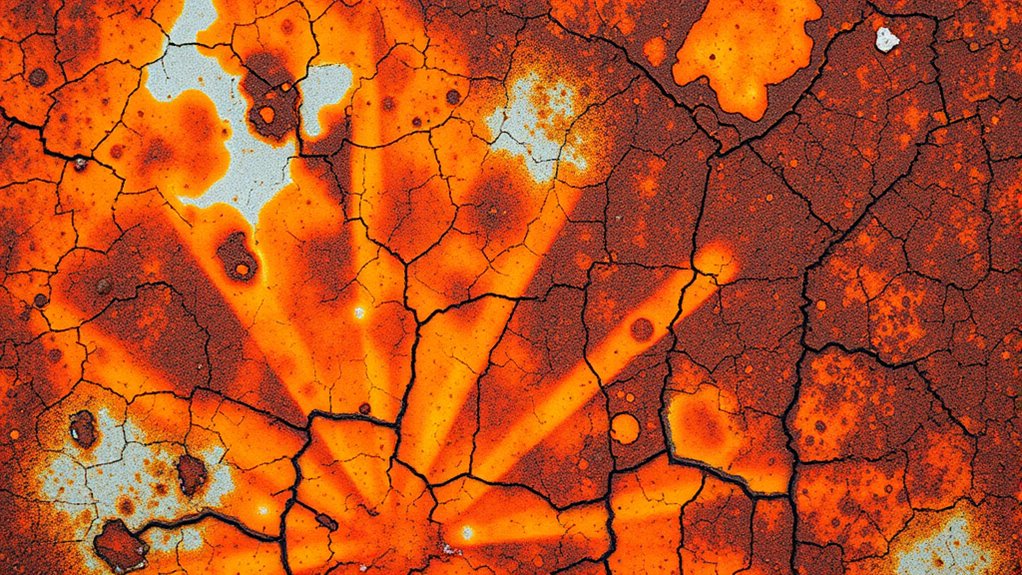

Have you ever wondered how rust begins to form on metal surfaces? It’s a slow process that often goes unnoticed until it’s advanced enough to cause real damage. Rust is fundamentally iron oxide, and it starts when the metal is exposed to moisture and oxygen. When water comes into contact with iron or steel, it reacts with the metal’s surface, initiating a chemical process called oxidation. This reaction creates tiny iron oxide particles that gradually grow and spread, weakening the metal over time. To combat this, many people turn to corrosion prevention methods, especially rust resistant coatings. These coatings act as a barrier, preventing moisture and oxygen from reaching the metal’s surface and stalling the rusting process before it even begins. Applying rust resistant coatings is one of the most effective ways to protect metal structures, tools, and equipment from corrosion, especially in harsh environments like coastal areas or industrial settings where exposure to moisture is constant.

Once rust starts to form, it doesn’t stay in one small spot. Instead, it tends to spread, especially if the initial protective layer has been compromised. As the rust develops, it eats away at the metal’s surface, creating flaky, rough patches that can flake off, exposing fresh metal underneath. This process accelerates as more moisture gets trapped in the tiny crevices, feeding the oxidation reaction. Over time, the structural integrity of the metal weakens, leading to potential failure. That’s why preventive measures are so vital. Regularly inspecting metal surfaces and maintaining protective coatings can make a big difference in halting the spread of rust. If you notice any damage or wear to the coating, it’s essential to reapply or repair it promptly to keep the underlying metal safe.

In addition to coatings, other corrosion prevention strategies include galvanization, which involves coating steel with a layer of zinc, and using rust inhibitors—chemical compounds that reduce rust formation. But the most straightforward and accessible method remains applying rust resistant coatings. They are easy to implement and highly effective at stopping rust before it starts or spreading further. Reapplication of protective coatings is crucial because once rust gains a foothold, it’s much harder to stop, and the damage can become costly. By proactively protecting your metal surfaces with proper coatings and maintenance, you’re ensuring their longevity and strength, saving you money and trouble in the long run. So, whether you’re working on a project, maintaining machinery, or safeguarding outdoor fixtures, understanding how rust begins and spreads empowers you to take the right preventive steps to keep your metal surfaces rust-free.

Frequently Asked Questions

Can Rust Be Completely Removed From Metal Surfaces?

Yes, rust can be completely removed from metal surfaces with proper rust removal techniques. You should start by cleaning the surface, then use abrasives or chemical rust removers to eliminate all traces of rust. Afterward, apply a metal preservative or rust-proof coating to prevent future corrosion. Regular maintenance and protective treatments are essential for metal preservation, ensuring your metal stays rust-free and in good condition for a long time.

How Long Does It Take for Rust to Form?

Rust can begin forming within hours if environmental factors like moisture, oxygen, and temperature are just right. The oxidation process starts almost immediately when metal is exposed to water and air, especially in humid conditions. If you leave metal surfaces unprotected, rust can develop quickly, sometimes in as little as a day or two. Regular maintenance and protective coatings help slow down this process considerably.

Are Some Metals More Resistant to Rust Than Others?

Yes, some metals resist rust better than others because of their metal composition. For example, stainless steel contains chromium, which forms a protective layer that prevents rust. You’ll find that environmental factors like humidity and exposure to salt accelerate rusting, especially on less resistant metals. So, choosing metals with specific compositions and considering environmental conditions helps you prevent or slow down rust formation effectively.

Does Rust Affect the Structural Integrity of Metal?

Rust acts like a slow poison, weakening metal over time. It definitely affects the structural integrity of metal by causing corrosion and creating weak spots. To combat this, you should use corrosion prevention techniques like applying rust resistant coatings. These coatings serve as a shield, preventing rust from forming and protecting the metal’s strength, ensuring your structures stay solid and safe longer.

Can Rust Spread Through Contact With Non-Metal Materials?

Yes, rust can spread through contact transfer to non-metal materials. When rusted metal touches objects like wood or fabric, tiny particles can transfer and cause rust spots or corrosion over time. To prevent this, you should practice rust prevention by handling rusted surfaces carefully and cleaning contact areas thoroughly. Wearing gloves and using protective coatings also help minimize contact transfer, reducing the risk of rust spreading to other materials.

Conclusion

Understanding how rust starts and spreads helps you protect your metal belongings. Remember, rust can begin in just 48 hours when exposed to moisture and oxygen, so quick action is key. Did you know that untreated rust can weaken metal by up to 60% within a year? Staying vigilant and applying protective coatings can save you money and extend the life of your items. Don’t wait—act now to keep rust at bay and preserve your metal surfaces.