Replacing a serpentine belt is a simple task that keeps your engine running smoothly. Start by noting the belt routing, then release tension with the tensioner or wrench. Remove the old belt and inspect all pulleys and tensioners for damage. Install the new belt, ensuring it follows the correct pattern and maintains proper tension. Double-check alignment and tension, and run the engine briefly to confirm everything operates smoothly. Keep going to learn detailed steps for a successful replacement.

Key Takeaways

- Proper belt tension prevents slipping, prolongs belt life, and ensures smooth engine operation.

- Follow the correct routing diagram and check pulley alignment before installation.

- Carefully remove the old belt, inspecting pulleys and tensioner for wear or damage.

- Install the new belt, adjusting tension as per vehicle specifications for optimal performance.

- Perform final checks on pulley alignment, belt tension, and run engine to verify proper installation.

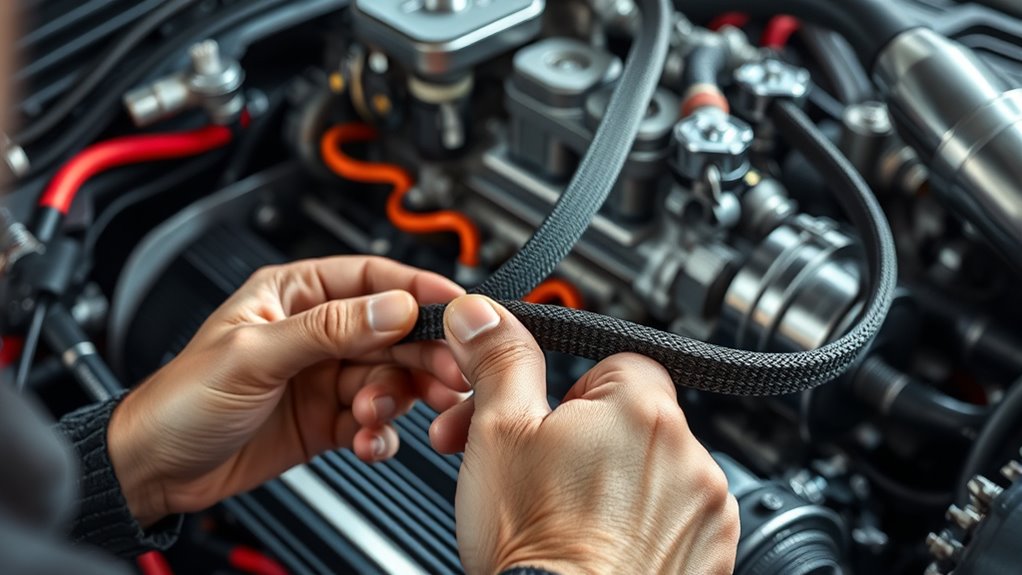

Replacing a serpentine belt yourself can save you money and time, especially if you’re comfortable working on your vehicle. When tackling this task, one of the most critical aspects is ensuring proper belt tension. Too tight, and you risk damaging pulleys and other accessories; too loose, and the belt might slip or come off entirely. To get this right, you need to understand how to check and adjust belt tension during installation. Many vehicles have a tensioner pulley that maintains the correct tension automatically, but in some cases, you may need to manually adjust the belt or replace the tensioner itself. Before removing the old belt, take note of its routing, either by drawing a diagram or taking a photo, so you can correctly route the new belt. Proper pulley alignment is also essential. Misaligned pulleys can cause the belt to wear prematurely or slip off. During installation, check that all pulleys are aligned correctly, and spin them by hand to confirm smooth rotation without wobbling or resistance. If you notice any pulley misalignment, you might need to replace or realign the pulleys before installing the new belt.

When removing the old belt, use a wrench or socket to release tension from the tensioner pulley if your vehicle has a manual tensioner. Carefully slip the belt off the pulleys, paying close attention to the routing pattern. Before installing the new belt, inspect all pulleys and tensioner components for wear or damage. A worn pulley or a faulty tensioner can cause your new belt to slip or wear out quickly. Once everything looks good, route the new belt according to your diagram or photo, ensuring it sits properly in the grooves of each pulley. Next, adjust the belt tension according to your vehicle’s specifications. Many tensioners are self-adjusting, but if yours requires manual tensioning, use a tension gauge or follow the manufacturer’s recommended deflection measurement. Proper tension ensures that the belt runs smoothly without slipping but isn’t overly tight to cause undue stress on the pulleys and bearings. Additionally, understanding the importance of pulley alignment can help prevent premature belt wear and ensure optimal performance.

After installing the belt, double-check pulley alignment and tension. Spin the pulleys by hand to confirm there’s no wobbling or resistance, and listen for any unusual noises once the engine runs. Running the engine briefly while observing the belt can help you spot issues like slipping or misalignment. In the end, doing this yourself not only saves you money but also gives you confidence in your vehicle’s maintenance. Just be sure to follow safety precautions, work carefully, and double-check each step for proper belt tension and pulley alignment.

Frequently Asked Questions

How Do I Identify the Correct Serpentine Belt Size for My Vehicle?

To identify the correct serpentine belt size for your vehicle, start by checking your owner’s manual or existing belt for the belt measurement, often listed in inches or millimeters. You can also remove the current belt and measure its length and width accurately. Guarantee belt compatibility by comparing your measurements with manufacturer specifications or using a belt size chart. This way, you get a perfect fit and avoid issues down the road.

Can I Replace a Serpentine Belt Without Professional Tools?

You can replace a serpentine belt without professional tools, but it depends on your vehicle and comfort level. Investigate whether your DIY tools include a belt tensioner tool or if you can use a simple wrench or screwdriver. Remember, proper belt tension is vital; too loose or tight can cause issues. While basic replacements are possible, make certain you understand the tension adjustment process to prevent future problems.

What Signs Indicate My Serpentine Belt Needs Replacement?

You’ll know your serpentine belt needs replacing if you notice it’s cracked, frayed, or shows signs of glazing. Also, if you experience squealing noises or the belt slips, it’s likely due to improper belt tension or pulley wear. Regularly inspect the belt for these issues, as tension problems and pulley wear can cause the belt to fail prematurely, so addressing these signs early can prevent breakdowns.

How Long Does a Typical Serpentine Belt Last?

A typical serpentine belt lasts between 60,000 to 100,000 miles, but this varies depending on belt material and vehicle age. Rubber belts tend to wear out faster, especially in older vehicles exposed to heat and debris. Regular inspections help catch signs of wear early. If your vehicle is older or has a rubber belt, expect to replace it closer to the lower end of that range.

Are There Specific Safety Precautions to Consider During Belt Replacement?

When replacing a serpentine belt, you should wear personal protective equipment like gloves and safety glasses to protect yourself from injury. Make certain vehicle lift safety by securely supporting your vehicle on a lift or jack stands before working underneath. Always disconnect the battery to prevent accidental engine start. Keep your workspace clean and free of debris, and follow all safety guidelines to avoid accidents or injuries during the process.

Conclusion

Replacing your serpentine belt yourself is like tuning a finely crafted instrument—you’ll feel the satisfying click of everything falling into place. With a little patience and the right tools, you’re the master conductor of your engine’s symphony. Remember, a well-maintained belt keeps your engine humming smoothly, preventing costly breakdowns. So, take charge, stay confident, and keep your car running like a well-oiled machine—because you’re the hero behind the wheel’s heartbeat.