If your engine is having trouble starting, idles roughly, or stalls unexpectedly, your crankshaft position sensor might be to blame. Common issues include damaged wiring, corrosion, electrical interference, or calibration problems that send incorrect signals to your engine control unit. Ensuring all connections are secure and wiring is intact can often fix the problem. If these steps don’t help, there are further troubleshooting options you can try to resolve the issue entirely.

Key Takeaways

- Faulty sensors can cause starting issues, engine stalls, rough idling, or no-start conditions.

- Wiring damage, corrosion, or loose connections disrupt signal transmission to the ECU.

- Electrical interference or calibration issues over time may lead to inaccurate sensor readings.

- Diagnosing involves inspecting wiring, checking connectors, and using scan tools for error codes like P0335.

- Proper calibration, wiring maintenance, and timely replacement restore engine performance and prevent sensor problems.

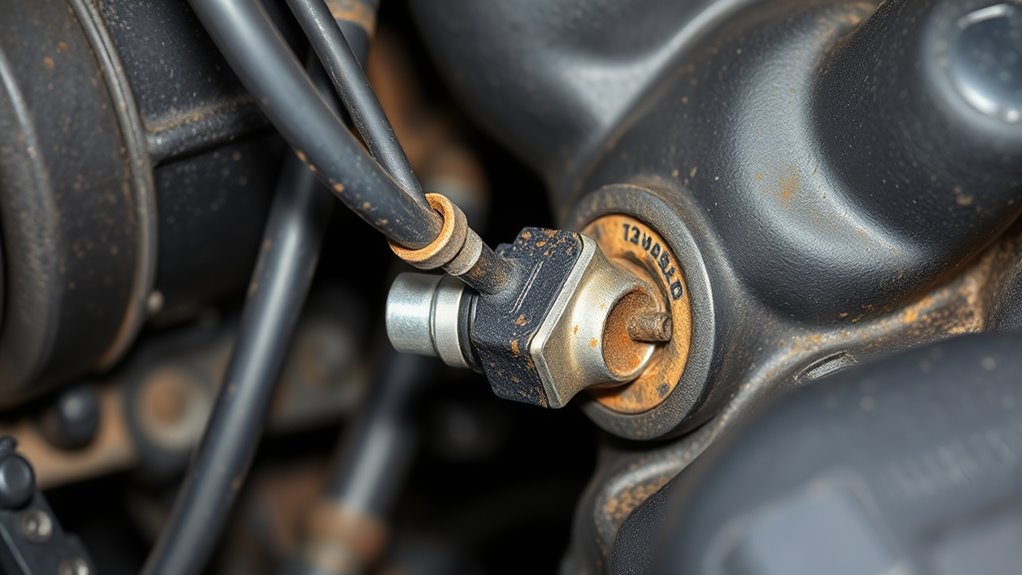

If your vehicle is experiencing starting issues, rough idling, or stalling, a faulty crankshaft position sensor could be the culprit. This sensor plays a crucial role in your engine’s operation, telling the engine control unit (ECU) the position of the crankshaft so it can manage fuel injection and ignition timing accurately. When the sensor malfunctions, you might notice your car struggles to start, runs unevenly, or stalls unexpectedly. One common cause of these problems is sensor calibration issues. Over time, exposure to heat, vibrations, or electrical interference can affect the sensor’s calibration, causing it to send incorrect signals to the ECU. If the sensor isn’t properly calibrated, the engine may receive faulty data, leading to poor performance or a no-start condition. Sometimes, recalibrating the sensor or replacing it altogether is necessary to restore proper engine function.

Wiring issues are another frequent source of crankshaft sensor problems. The sensor relies on a network of wires and connectors to transmit signals to the ECU. Damaged or corroded wiring can disrupt this communication, resulting in inconsistent or lost signals. You might notice erratic engine behavior, such as sudden stalls or misfires. Frayed wires, loose connections, or corrosion can all compromise the integrity of the wiring harness. It’s essential to inspect the wiring thoroughly if you suspect sensor issues. Sometimes, a simple repair—like cleaning connectors, sealing against moisture, or replacing damaged wires—can resolve the problem. However, if wiring issues persist, the entire harness may need replacing to ensure reliable signal transmission. Additionally, sensor calibration can be affected by external factors such as electrical interference, emphasizing the importance of proper shielding and grounding.

Diagnosing sensor calibration and wiring issues requires attention to detail. Using a scan tool, you can check for error codes related to the crankshaft position sensor. Codes such as P0335 indicate a problem with the sensor circuit. When you’re inspecting the wiring, look for visible signs of damage or corrosion, especially around connectors and along the harness. Make sure all connections are secure and free of debris. If calibration is suspected to be off, some vehicles allow for sensor calibration or relearn procedures, which can often be performed with specialized diagnostic equipment. Otherwise, replacing the sensor might be your best option.

Frequently Asked Questions

How Long Does a Crankshaft Position Sensor Typically Last?

A crankshaft position sensor usually lasts between 60,000 and 100,000 miles, depending on your driving conditions and sensor quality. You might need to replace it sooner if you notice issues like engine misfires or stalling. While there aren’t strict replacement intervals, keeping an eye on sensor lifespan and proactively replacing it when symptoms appear can prevent unexpected breakdowns. Regular maintenance helps guarantee your vehicle runs smoothly.

Can I Drive My Car With a Faulty Crankshaft Sensor?

You shouldn’t drive your car with a faulty crankshaft sensor, as it can cause engine stalling and misfires. A problematic sensor may lead to inaccurate sensor calibration, affecting engine performance. Continuing to drive risks further damage and unsafe driving conditions. It’s best to get it checked and replaced promptly to guarantee your engine runs smoothly and reliably, preventing costly repairs down the line.

What Are the Signs of Intermittent Crankshaft Sensor Failure?

You’ll notice signs of intermittent crankshaft sensor failure when your engine stalls unexpectedly, especially during acceleration or idling. Watch for erratic engine behavior, rough idling, or difficulty starting. Check the sensor wiring for loose connections or damaged wires, as these issues can cause inconsistent signals. If you experience these symptoms, it’s essential to get your sensor inspected and repaired promptly to prevent further engine problems.

How Much Does It Cost to Replace a Crankshaft Position Sensor?

Replacing your crankshaft position sensor costs between $150 and $350, depending on your vehicle and location. You’ll likely need sensor calibration afterward, which adds to the cost. The process involves basic replacement tools like a socket set and possibly a diagnostic scan tool. You can save some cash by doing it yourself or seeking out a mechanic, but make certain you get quality parts for reliable performance.

Are There Any DIY Methods to Troubleshoot Crankshaft Sensor Issues?

Yes, you can troubleshoot crankshaft sensor issues yourself. Start with sensor testing using a multimeter to check for proper resistance. Next, inspect the wiring for any damage, corrosion, or loose connections. Make sure all connectors are secure. If the sensor fails the resistance test or wiring looks compromised, replacing or repairing it may be necessary. Always make certain the engine is off before inspecting or testing to avoid injury.

Conclusion

If your vehicle’s crankshaft position sensor starts acting up, don’t ignore it—about 30% of engine stalls are linked to sensor issues. Fixing it early can save you time and money, preventing costly repairs down the line. Remember, a faulty sensor can cause poor acceleration, rough idling, or even engine failure. Staying vigilant and addressing problems promptly keeps your engine running smoothly and helps you avoid unexpected breakdowns on the road.