Seam sealers are essential in vehicle repairs and manufacturing because they help you lock out moisture, preventing rust and corrosion, and guaranteeing long-term durability. If you don’t apply them properly, you risk trapping air bubbles, leaving gaps, or using incompatible materials, which can cause cracking or peeling over time. Proper surface prep and correct application are vital to avoid these common failures. Keep going to discover how to guarantee your sealers last longer and protect your vehicle effectively.

Key Takeaways

- Seam sealers prevent moisture intrusion, rust, and corrosion, ensuring vehicle durability and structural integrity.

- Proper application involves cleaning, continuous bead application, and smoothing for effective sealing.

- Common failures include air bubbles, gaps, excess material, and improper curing, leading to water ingress and material breakdown.

- Environmental factors and material compatibility are critical; wrong sealers or conditions cause early deterioration.

- Correct sealing practices reduce defects, maintain long-term protection, and prevent costly repairs.

Have you ever wondered why seam sealers are essential in vehicle manufacturing and repair? These materials are critical for sealing joints, preventing moisture intrusion, and ensuring the vehicle’s longevity. To get the best results, understanding proper application techniques is vital. When applying seam sealer, you need to prepare the surface thoroughly by cleaning and removing rust or old sealant. Using the right tools, like a caulking gun or a specialized nozzle, helps you control the flow and achieve a consistent bead. Applying the sealer in a continuous, even layer ensures there are no gaps or thin spots that could compromise the seal. You should also pay attention to the temperature and humidity conditions, as these can affect how well the sealer cures and adheres. After application, smooth out the bead with a spatula or your finger (wearing gloves), to ensure a seamless finish that bonds properly with the surrounding surfaces. Proper technique not only guarantees durability but also minimizes the risk of future failures.

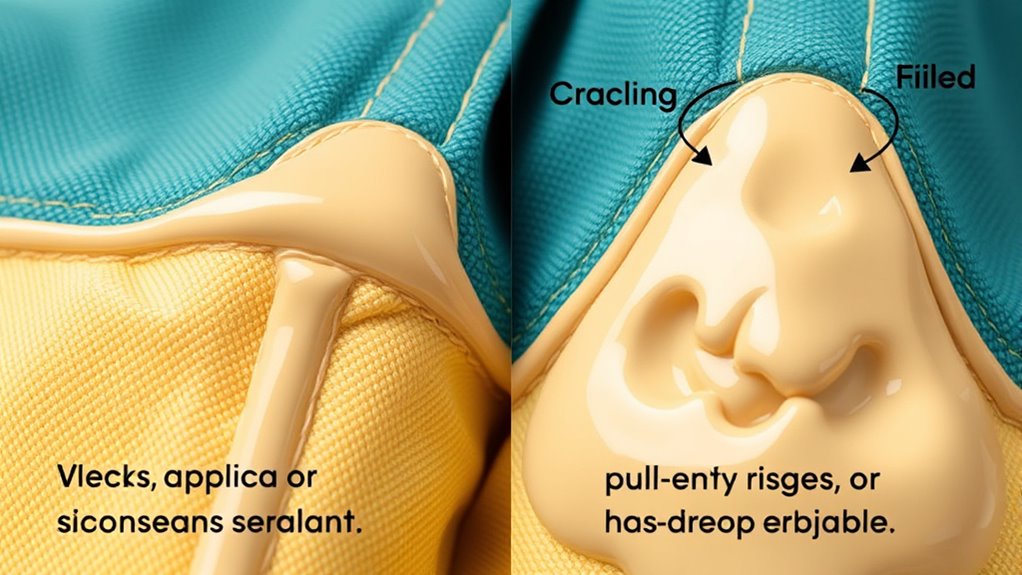

However, even with careful application, common defects can occur if the process isn’t followed correctly. Air bubbles or voids in the sealant can develop if the application is rushed or if the surface isn’t properly prepared. These defects weaken the seal and allow moisture or debris to penetrate, leading to rust and corrosion over time. Over-application or excess material can cause shrinkage or sagging, which reduces the effectiveness of the seal. Conversely, under-application leaves gaps where water can seep in, risking damage to internal components. Improper curing or applying sealer in unsuitable environmental conditions can also lead to failures, such as cracking or peeling. Additionally, using the wrong type of seam sealer for specific materials or environments can result in poor adhesion and early deterioration. For example, a sealer designed for metal might not bond well with plastic or composite parts, causing it to fail prematurely.

Understanding these common defects underscores the importance of following correct application techniques and selecting the right product for each job. When you pay close attention to the surface prep, application method, and environmental factors, you considerably reduce the chances of failure. Remember that seam sealers are a long-term investment in your vehicle’s integrity, so doing it right the first time saves you time, money, and headaches down the road. Proper application and awareness of potential defects ensure your vehicle remains protected from the elements and maintains its structural integrity for years to come.

Frequently Asked Questions

How Long Does Seam Sealer Typically Last?

Seam sealer typically lasts about 5 to 10 years, depending on application longevity and sealing durability. If applied correctly and with quality materials, it can withstand weather, moisture, and stress for many years. You should check it regularly for cracks or deterioration, especially after extreme temperatures or heavy use. Proper maintenance and timely reapplication guarantee your seams stay protected and maintain their sealing effectiveness over time.

Can Seam Sealer Be Removed Easily?

Removing seam sealer is like peeling off a sticker—you can do it, but it takes some effort. You’ll want to use proper removal techniques, starting with gentle scraping and then applying solvent options like rubbing alcohol or commercial seam sealer remover. Be patient and work carefully to avoid damaging the underlying surface. Always test a small area first, and follow safety instructions on the solvents for best results.

Is Seam Sealer Suitable for All Vehicle Types?

Seam sealer isn’t suitable for all vehicle types. You should look for products with universal compatibility or vehicle-specific formulations to guarantee proper adhesion and flexibility. Using the right sealer helps prevent leaks and corrosion. Check your vehicle’s materials and manufacturer recommendations before applying seam sealer. This way, you ensure a durable, effective seal that won’t cause issues down the road.

What Environmental Factors Affect Seam Sealer Performance?

Environmental factors like moisture, temperature fluctuations, and UV exposure directly impact seam sealer performance. You need to guarantee it offers good weather resistance to withstand rain and sun, preventing corrosion and rust formation. Excessive humidity accelerates deterioration, while extreme temperatures can cause cracking or peeling. To maintain effective corrosion prevention, choose a seam sealer formulated for your climate, and regularly inspect and reapply if you notice any damage or wear.

How Can I Tell if Seam Sealer Needs Reapplication?

You can tell if your seam sealer needs reapplication by inspecting for cracks, peeling, or gaps in the seal. Proper application techniques ensure durability, so check if the sealer was applied evenly and with compatible materials. If you notice any deterioration or if the seal no longer adheres well, it’s time to reapply. Regular inspections help maintain a weatherproof barrier and prevent moisture intrusion.

Conclusion

So, now you know seam sealer’s true mission: to keep water out and rust at bay—unless, of course, it decides to give up and let moisture in. When failures happen, it’s like a betrayal from your trusted armor, turning your vehicle into a soggy mess. But hey, who needs dry, rust-free cars when you can have a soggy, rusty masterpiece? Just remember, a little maintenance might save you from becoming the next underwater adventure.