To test your EVAP system, start with a visual inspection for damage or leaks. Use a smoke machine to introduce harmless smoke and spot any escape points. Perform pressure or vacuum tests to see if the system maintains proper pressure over time. Electronic leak detectors can pinpoint even tiny vapor leaks with high accuracy. Keep in mind that proper testing guarantees environmental compliance and vehicle efficiency—continue exploring to discover detailed methods and best practices.

Key Takeaways

- Visual inspection checks for physical damage, leaks, and loose connections in hoses, fittings, and valves.

- Smoke machine testing introduces smoke to identify small leaks in the EVAP system visually.

- Pressure or vacuum tests monitor pressure stability over time to detect leaks through sudden drops.

- Electronic leak detection measures vapor loss with high accuracy, suitable for complex or aged systems.

- Proper testing ensures environmental compliance, prevents emissions issues, and helps avoid costly repairs.

The EVAP (Evaporative Emission Control) system plays a crucial role in reducing fuel vapors released into the atmosphere, making it necessary to perform accurate tests to guarantee its proper functioning. When testing the system, your primary goal is to guarantee that fuel vapor doesn’t escape from the sealed environment of your vehicle’s fuel system. Fuel vapor leaks are a major concern because they contribute to pollution and can trigger emissions-related warning lights. Detecting leaks early helps prevent costly repairs and keeps your vehicle compliant with environmental standards.

Leak detection is at the core of EVAP system testing. You’ll typically start by inspecting the entire fuel system for obvious signs of damage or deterioration, such as cracked hoses, loose fittings, or damaged valves. Once visually inspected, you move on to more systematic testing methods. One common approach involves using a smoke machine, which introduces harmless smoke into the EVAP system. If there’s a leak, the smoke escapes at the fault point, immediately alerting you to where the leak is located. This method is quick, effective, and allows you to pinpoint even small leaks that might otherwise go unnoticed.

Leak detection begins with visual inspection, then uses smoke machines to quickly identify even small EVAP system leaks.

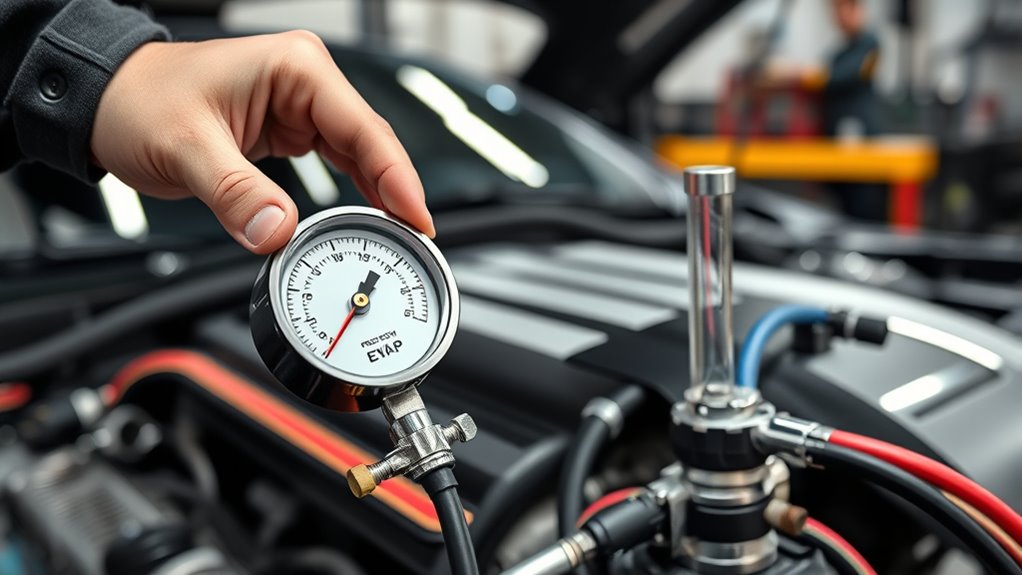

Another key testing method involves pressure or vacuum tests. You’ll connect a specialized tester to the system’s port and either pressurize or create a vacuum within the sealed environment. Then, you monitor the pressure over a period of time. If the pressure drops unexpectedly, it indicates a leak somewhere in the system. These tests are precise and can be performed with various tools, giving you a clear indication of whether the system is holding the proper vacuum or pressure as it should. Additionally, maintaining a properly sealed system is essential for accurate testing results and proper emission control.

In addition to physical inspections and pressure tests, many technicians use electronic leak detection tools. These devices can measure the rate of vapor loss or detect minute leaks that might be invisible to the naked eye. Electronic testing provides a high level of accuracy, especially for vehicles with complex or aged EVAP systems where leaks might be very small. When conducting these tests, it’s crucial to follow manufacturer guidelines closely to guarantee valid results.

Performing these tests diligently helps you maintain the integrity of the EVAP system, ensuring that fuel vapors are contained and not released into the environment. By systematically inspecting for leaks and verifying the system’s integrity, you prevent unnecessary emissions, improve vehicle efficiency, and avoid potential failures that could lead to costly repairs down the line. Proper leak detection and fuel vapor testing are critical steps in keeping your vehicle running clean and efficiently.

Frequently Asked Questions

How Often Should EVAP Systems Be Tested During Vehicle Maintenance?

You should test your EVAP system during regular maintenance schedules, typically every 30,000 to 50,000 miles or as recommended by your vehicle’s manufacturer. Using diagnostic tools, you can effectively identify leaks or faults. Regular testing guarantees your vehicle stays emissions-compliant, prevents costly repairs, and maintains fuel efficiency. Make sure to follow the maintenance schedule closely and rely on proper diagnostic tools for accurate results.

Can EVAP System Tests Detect All Leaks Accurately?

Think of EVAP system tests as your vehicle’s lie detector. They can spot many leaks, but not all, because some are too tiny or hidden for detection. While leak detection methods improve testing accuracy, they might miss very small or complex leaks. You should trust these tests as a strong tool, but also stay alert for signs of EVAP issues, knowing that some leaks could still slip through.

Are There Specific Vehicle Models That Require Special Testing Procedures?

Yes, some vehicle models require model-specific tests and manufacturer procedures. You need to follow these special testing methods because they account for unique EVAP system designs or materials. Always consult the manufacturer’s guidelines to guarantee accurate diagnostics. Using the correct procedures helps you detect leaks effectively and prevents false readings. Sticking to model-specific tests ensures your EVAP system assessments are precise, saving you time and reducing the risk of missed leaks.

How Long Does an EVAP System Test Typically Take?

You’ll find that an EVAP system test usually takes about 30 to 60 minutes. During the process, you’ll check the fuel tank and vapor line for leaks or blockages. The technician often performs pressure tests and inspects hoses, ensuring the system seals properly. This quick yet thorough check helps confirm the integrity of your vehicle’s EVAP system, preventing emissions issues and keeping your car running smoothly.

What Are Common Signs Indicating an EVAP System Failure?

You might notice your vehicle’s check engine light turning on, which often indicates an evap system failure. Common signs include difficulty filling your gas tank, a strong fuel smell, or reduced fuel efficiency. During diagnostic procedures, technicians check evap system components like the vent valve, purge valve, and fuel cap for leaks or malfunctions. These signs help identify issues requiring repair to prevent further emissions problems and ensure your vehicle runs smoothly.

Conclusion

So, now that you’ve mastered EVAP system test methods, you’re practically a detective of fuel vapors. Who knew sniffing, pressure testing, and smoke machines could be so thrilling? Just remember, in the grand quest to prevent leaks, your keen eye and quick wit are your best tools. After all, nothing says “car hero” quite like catching that tiny vapor escape before it becomes a full-blown crisis. Happy testing—may your seals be tight and your fumes be minimal!