Oxygen sensors produce analog voltage signals that fluctuate based on exhaust oxygen levels, helping your ECU maintain a proper air-fuel mixture. AFR sensors give real-time, precise digital signals reflecting the exact ratio of air to fuel, aiding fine-tuned engine control. While oxygen sensors focus on stoichiometry, AFR sensors provide broader ratio insights. Understanding these differences can improve diagnostics and tuning—if you want to get the most out of your engine, it’s worth exploring how each signal works in detail.

Key Takeaways

- Oxygen sensors generate voltage signals based on exhaust oxygen levels, indicating rich or lean conditions, while AFR sensors provide direct, real-time AFR measurements.

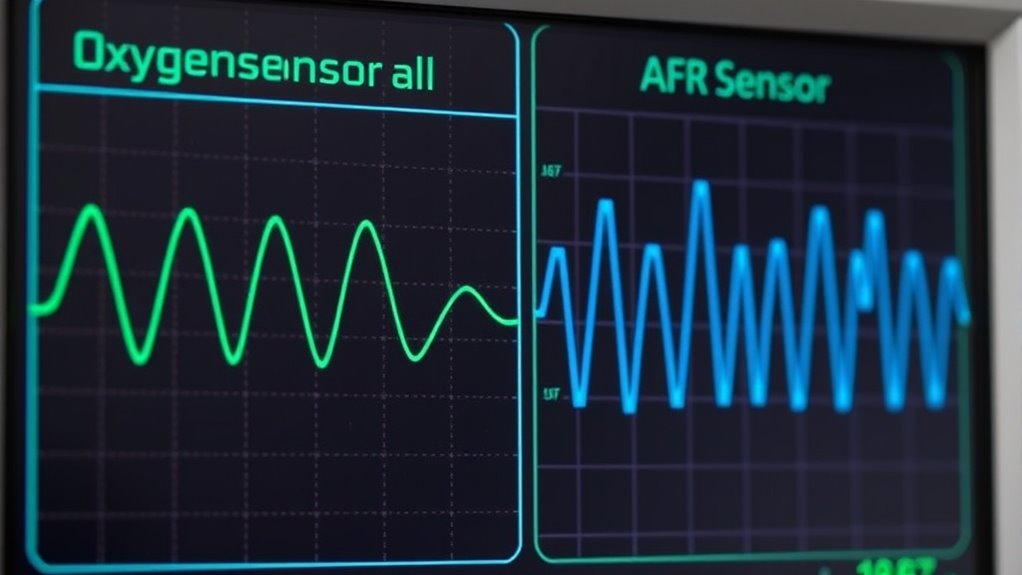

- Oxygen sensor signals are typically analog and fluctuate rapidly, requiring filtering, whereas AFR sensors often produce more stable, digitally processed data.

- AFR sensors are calibrated to deliver precise AFR readings, offering detailed mixture insights, unlike oxygen sensors which primarily signal stoichiometric balance.

- Both sensors support engine management, but AFR sensors enable finer tuning and performance optimization through accurate ratio data.

- Advances in AI enhance calibration and signal interpretation for both sensor types, improving diagnostics, fuel efficiency, and emissions control.

Understanding the difference between oxygen sensor signals and AFR sensor signals is essential for diagnosing and tuning your vehicle’s engine performance. Both sensors provide crucial data, but they serve different purposes and produce distinct signals that influence how your engine runs. Grasping these differences helps you optimize your vehicle’s efficiency and ensures accurate diagnostics.

Understanding oxygen and AFR sensor signals is key to optimizing engine performance and diagnostics.

Oxygen sensors, typically narrowband or wideband, measure the amount of oxygen in the exhaust gases. They generate voltage signals based on the oxygen content, which the engine control unit (ECU) interprets to maintain the ideal air-fuel mixture. When it comes to sensor calibration, you need to ensure that the oxygen sensor is functioning correctly and providing precise signals. Proper calibration involves checking the sensor’s response to known oxygen levels and ensuring it’s within manufacturer specifications. Signal processing is vital here because the raw voltage signals can be noisy or fluctuating. Many ECUs apply filtering algorithms or digital signal processing techniques to smooth out the data, allowing for more accurate fuel adjustments. If the signal processing isn’t handled properly, the ECU might misinterpret the oxygen levels, leading to poor fuel economy, increased emissions, or drivability issues.

On the other hand, AFR sensors, or air-fuel ratio sensors, typically use wideband technology to provide a more precise measurement of the actual ratio of air to fuel in the exhaust. These sensors output a signal that directly correlates with the AFR, giving a real-time, detailed view of how close your mixture is to the optimal ratio. Because of their role in providing detailed feedback, AFR sensors require meticulous sensor calibration to ensure their readings match the true AFR. Accurate calibration involves comparing sensor outputs against known standards and adjusting the sensor or ECU parameters accordingly. Signal processing is also critical here—since AFR sensors produce complex, often digital signals, the ECU must interpret these signals correctly. Proper signal processing ensures that the data reflects true engine conditions, enabling the ECU to make precise fuel adjustments. This is especially important in high-performance or emissions-sensitive applications.

Furthermore, recent advancements in AI develops innovative solutions for sensor calibration and signal interpretation are enhancing the accuracy and reliability of both oxygen and AFR sensors. In essence, understanding how sensor calibration and signal processing work for both oxygen and AFR sensors is key to maintaining peak engine performance. While oxygen sensors focus more on maintaining a stoichiometric mixture for emissions control, AFR sensors provide a broader, more detailed view of the mixture’s precision. Knowing how each sensor’s signals are generated, processed, and calibrated allows you to troubleshoot issues effectively and fine-tune your vehicle for better efficiency, power, and emissions compliance.

Frequently Asked Questions

How Do Sensor Signals Affect Overall Engine Performance?

The sensor signals directly impact your engine’s performance by ensuring proper air-fuel mixture. When sensors are well-calibrated and signal processing is accurate, your engine runs smoothly, improving fuel efficiency and reducing emissions. Poor calibration or faulty signal processing can cause misfires, power loss, or increased fuel consumption. Regularly check and maintain your sensors to keep signals accurate, so your engine performs at its best and responds quickly to driving demands.

Can Faulty Sensors Cause Increased Fuel Consumption?

A misstep in sensor calibration can quietly lead to increased fuel consumption, subtly affecting your vehicle’s efficiency. Faulty sensors may send inaccurate signals, causing your engine to work harder and consume more fuel. This not only impacts your wallet but also hampers emission control efforts. Regularly checking and maintaining your sensors guarantees smoother performance, keeps emissions in check, and saves you money by preventing unnecessary fuel use.

Are Oxygen Sensors and AFR Sensors Interchangeable?

No, oxygen sensors and AFR sensors aren’t interchangeable. You need to ensure sensor calibration and compatibility because they serve different functions; oxygen sensors measure exhaust gases to help the ECU adjust fuel mixture, while AFR sensors provide a direct readout of air-fuel ratio. Using the wrong sensor can lead to incorrect readings, impacting performance. Always check the manufacturer’s specifications to ensure you select the right sensor for your vehicle.

What Are Common Signs of Sensor Failure?

You’ll notice sensor failure through symptoms like rough idling, decreased fuel efficiency, and increased emissions. You might also see the check engine light illuminate. Using diagnostic tools, you can identify issues with sensor calibration or faulty signals. These signs indicate the sensor isn’t providing accurate data, so addressing them promptly guarantees your vehicle runs smoothly and efficiently, preventing further damage and costly repairs.

How Often Should Sensors Be Tested or Replaced?

You should test your sensors during regular maintenance, typically every 30,000 to 50,000 miles, or as recommended by your vehicle’s manufacturer. Sensor calibration is essential for accurate readings, so consider recalibrating if you notice performance issues. Replacement intervals vary, but generally, sensors need replacing every 60,000 to 100,000 miles. Keep an eye on signs of failure and follow your vehicle’s maintenance schedule to guarantee peak performance.

Conclusion

So, next time you’re diagnosing engine issues, remember that both oxygen sensors and AFR sensors play vital roles—and often, their signals intertwine unexpectedly. It’s no coincidence that understanding the subtle differences can lead to pinpointing problems faster. By paying attention to both sensors, you might just catch a hidden fault before it causes major damage. In the end, recognizing their connection helps you keep your engine running smoothly—proving that sometimes, luck favors the prepared.