To understand oscilloscope basics for engine diagnosis, you need to know it helps you visualize electrical signals from sensors and engine parts in real time. By connecting the probes, you can see waveform patterns that indicate whether sensors are working properly or if faults exist. Recognizing these signals allows you to quickly identify issues like faulty sensors, wiring problems, or corrosion. Continuing will help you master waveform analysis and improve your troubleshooting skills.

Key Takeaways

- An oscilloscope visualizes engine sensor signals over time, aiding in accurate diagnosis.

- Proper connection of probes to sensors allows real-time waveform observation for troubleshooting.

- Analyzing waveforms’ shape, amplitude, and frequency helps identify faulty or malfunctioning sensors.

- Recognizing abnormal or distorted signals indicates wiring issues, corrosion, or sensor faults.

- Waveform patterns and real-time visualization enhance diagnostic speed and improve fault detection accuracy.

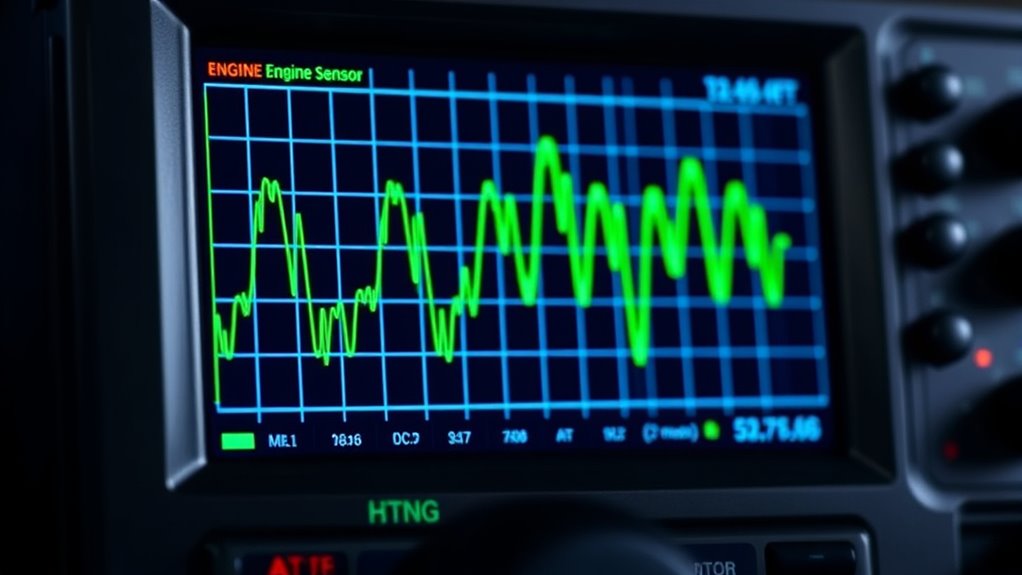

An oscilloscope is an indispensable tool for visualizing electrical signals, allowing you to see how voltage varies over time. When diagnosing engine problems, this device becomes invaluable, especially for sensor testing. Many engine sensors generate electrical signals that directly influence engine performance. By attaching the oscilloscope probes to these sensors, you can observe their output waveforms in real-time. This helps you determine whether a sensor is functioning correctly or if it’s producing abnormal signals. For example, a faulty coolant temperature sensor might produce a flat or erratic waveform, indicating it’s not providing accurate data to the engine control unit (ECU). Understanding what to look for during sensor testing saves you time and prevents unnecessary replacements. Additionally, the integration of automation technologies in diagnostic tools can further enhance accuracy and efficiency in identifying issues.

Waveform interpretation is at the heart of using an oscilloscope effectively in engine diagnostics. Once you’ve connected the device, you’ll see a visual representation of the signal. Your job then is to analyze the waveform’s shape, amplitude, frequency, and timing. For instance, a clean, consistent waveform from a sensor typically indicates normal operation, while irregular shapes suggest issues. Recognizing patterns helps you diagnose problems quickly. For example, a sensor signal that shows a distorted or noisy waveform might point to wiring problems, corrosion, or a failing sensor. Learning to interpret these waveforms accurately allows you to pinpoint specific issues without guesswork, making your diagnosis more precise.

Frequently Asked Questions

What Are the Common Mistakes to Avoid When Using an Oscilloscope for Engine Diagnosis?

To prevent misinterpretation pitfalls when using an oscilloscope for engine diagnosis, you should double-check equipment calibration before starting. Avoid rushing through setup, which can lead to incorrect readings. Make sure your probes are properly connected and grounded. Stay aware of potential signal noise and interference. Also, don’t overlook the importance of understanding the engine’s normal signals to accurately diagnose issues without jumping to conclusions.

How Do I Interpret Complex Waveform Patterns in Engine Diagnostics?

When interpreting complex waveform patterns, focus on waveform analysis and signal interpretation. Look for consistent patterns that match known engine signals, such as ignition or sensor outputs. Break down the waveform into sections, identify anomalies like noise or irregular spikes, and compare them to reference waveforms. Use your knowledge of engine functions to understand what each pattern indicates, helping you diagnose issues accurately and efficiently.

Can Oscilloscopes Detect All Types of Engine Faults Effectively?

Oscilloscopes can detect many engine faults effectively, especially with features like digital storage and signal filtering. Digital storage allows you to capture and review complex waveforms for detailed analysis, while signal filtering helps remove noise, making faults more visible. However, they might not catch all issues, especially those that require specific sensors or diagnostic tools. Combining oscilloscopes with other testing methods ensures a thorough engine diagnosis.

What Safety Precautions Should I Follow When Working With Oscilloscopes on Engines?

Did you know that improper handling of oscilloscopes can lead to electrical hazards? When working on engines, always wear appropriate safety gear like insulated gloves and eye protection to prevent shocks. Keep the workspace dry and make sure the engine is off before connecting the scope. Be cautious of high-voltage areas and avoid touching exposed wires. Following these safety precautions helps protect you from potential injuries and ensures accurate diagnostics.

How Does Ambient Temperature Affect Oscilloscope Readings During Engine Testing?

Ambient effects, like temperature, can cause fluctuations in your oscilloscope readings during engine testing. Higher or lower temperatures impact the scope’s components, leading to inaccuracies. To minimize this, you should perform temperature calibration before testing and guarantee the environment remains stable. This way, you maintain precise measurements, and your diagnostic results stay reliable regardless of ambient temperature changes.

Conclusion

Now that you know the basics of using an oscilloscope for engine diagnosis, you’re better equipped to troubleshoot with confidence. Think of it as your modern equivalent of a stethoscope, but for cars—no need for a crystal ball. With a little practice, you’ll be reading waveforms like a seasoned mechanic from the days of the Model T. Keep honing your skills, and soon you’ll diagnose engine issues faster than you can say “Eureka!”