To fix battery cable corrosion, start by disconnecting the cables carefully with the vehicle off. Use a mixture of baking soda and water to scrub away the corrosion with a wire brush or terminal cleaner. Rinse, dry thoroughly, and then apply a protective layer like petroleum jelly or a corrosion inhibitor. Keeping the terminals clean and dry helps prevent future buildup. If corrosion persists or cables are damaged, replacing them guarantees reliable connections. Continue with tips that can help maintain your battery’s health.

Key Takeaways

- Disconnect the battery cables carefully before cleaning to prevent electrical hazards.

- Use a baking soda and water solution with a wire brush to remove corrosion effectively.

- Rinse, dry thoroughly, and apply a protective layer like petroleum jelly or terminal grease.

- Replace severely damaged or corroded cables to ensure reliable electrical connections.

- Regularly inspect and maintain battery terminals to prevent future corrosion buildup.

If your vehicle’s battery cables are corroded, it can lead to starting problems and electrical issues. Corrosion buildup is a common culprit behind weak connections, preventing your battery from delivering power efficiently. To address this, you need to focus on corrosion prevention and, when necessary, cable replacement. Taking these steps can restore proper function and help avoid future complications.

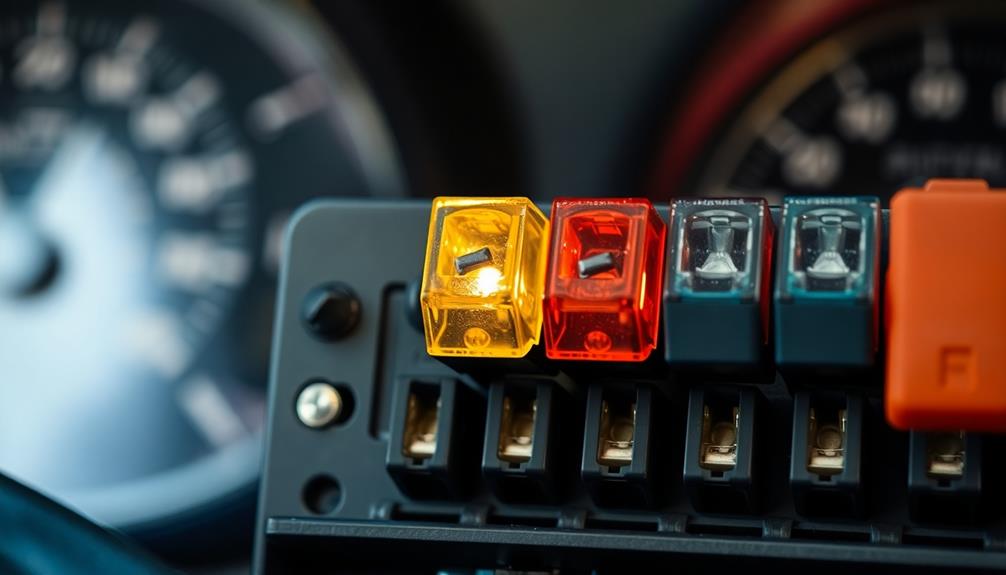

First, assess the extent of corrosion on your battery cables. You might notice a white or greenish powdery substance on the terminal ends or along the cable insulation. If corrosion is minor, you can often clean it off using a mixture of baking soda and water. Disconnect the cables carefully, ensuring the vehicle is off and the keys are out of the ignition. Wear gloves to protect your skin from any harsh residues. Use a wire brush or a terminal cleaner to scrub away corrosion, then rinse with water and dry thoroughly. After cleaning, apply a thin layer of petroleum jelly or a commercial corrosion inhibitor to the terminals to help prevent future buildup.

However, if corrosion has severely damaged the cables, corrosion prevention alone won’t suffice. In this case, cable replacement is your best option. Damaged cables can cause inconsistent electrical flow, which may lead to starting failures or even electrical system failures. Replacing faulty cables ensures a secure, corrosion-free connection. When choosing replacement cables, opt for high-quality, OEM-grade parts that fit your vehicle’s specifications. Installing new cables involves disconnecting the old ones, attaching the new cables securely to the battery terminals, and ensuring the connections are tight and free of corrosion. Proper installation is vital to prevent future issues, so consider tightening the clamps firmly and inspecting for any signs of wear or damage.

Regular maintenance plays a significant role in corrosion prevention. Periodically check your battery terminals and cables, especially during extreme weather conditions or if you notice sluggish engine starts. Applying protective sprays or terminal grease after cleaning helps shield the cables from moisture and corrosive elements. Keeping your battery area clean and dry also reduces the risk of corrosion buildup. Remember, addressing corrosion early can save you from more costly repairs down the line and guarantee your vehicle runs smoothly.

Frequently Asked Questions

How Often Should I Inspect Battery Cables for Corrosion?

You should inspect your battery cables for corrosion at least once every three to six months. Regular inspection frequency helps you detect corrosion early before it causes starting issues or electrical problems. During each check, look for white, green, or bluish deposits around the terminals and cable ends. Prompt corrosion detection allows you to clean and maintain your battery connections, ensuring peak performance and prolonging the life of your vehicle’s electrical system.

Can Corrosion Cause Electrical System Failures?

Corrosion impact can definitely cause electrical failures in your vehicle. When battery cable corrosion builds up, it hampers the flow of electricity, leading to starting problems, dim lights, or even complete electrical system failure. If you notice corrosion on your cables, it’s essential to clean and inspect them regularly. Ignoring corrosion increases the risk of electrical failures, which can leave you stranded or cause more serious engine issues down the line.

Are There Environmentally Friendly Corrosion Prevention Methods?

Yes, there are eco-friendly corrosion prevention methods you can use. You might apply eco-friendly coatings that protect against corrosion without harming the environment. Additionally, biodegradable inhibitors are effective options; they temporarily prevent corrosion but break down naturally over time. By choosing these environmentally friendly solutions, you help reduce chemical waste and minimize ecological impact, all while keeping your battery cables protected from corrosion.

What Are the Signs of Severe Battery Cable Corrosion?

Imagine your battery terminal as a fortress, and corrosion buildup as creeping vines overtaking its walls. When you see greenish or white powder on the battery terminal or cables, it’s a sign of severe corrosion. If the connections feel loose or are difficult to remove, the corrosion has likely compromised the cable’s integrity. These signs indicate the corrosion is advanced, risking poor electrical contact and potential starting issues.

How Do I Safely Dispose of Corroded Battery Cables?

To safely dispose of corroded battery cables, you should first wear protective gloves and goggles. Then, take the cables to a certified battery recycling center, as they handle hazardous waste properly. Avoid throwing them in regular trash to prevent environmental harm. Proper disposal guarantees hazardous waste is managed safely and helps promote battery recycling efforts, protecting both you and the environment from potential dangers posed by the corrosion.

Conclusion

By keeping your battery cables clean and corrosion-free, you’re giving your vehicle a fighting chance to start strong every time. Think of it as tending to the roots of a healthy tree—neglect, and everything above suffers. A simple fix now can prevent costly repairs later, ensuring your car stays reliable like a loyal friend. Don’t let corrosion corrode your peace of mind—act today, and keep your journey smooth and worry-free.