To properly test a battery, start by performing load tests that simulate real-world use to evaluate capacity and internal resistance. Use specialized testing equipment like battery analyzers for accurate data, and follow standardized procedures to guarantee consistency. Regularly monitor parameters such as voltage, charge retention, and internal resistance to identify aging or damage. Maintaining a controlled testing environment can improve accuracy. Continue exploring effective methods to keep your batteries in top condition.

Key Takeaways

- Follow standardized testing procedures, including load tests and parameter measurements, for consistent and reliable results.

- Use specialized equipment like battery analyzers to assess internal resistance and capacity accurately.

- Ensure proper connection of testing devices according to manufacturer guidelines to avoid measurement errors.

- Interpret data such as capacity loss and internal resistance increase to determine battery health and replacement needs.

- Conduct regular monitoring and testing in controlled environments to track aging trends and maintain optimal performance.

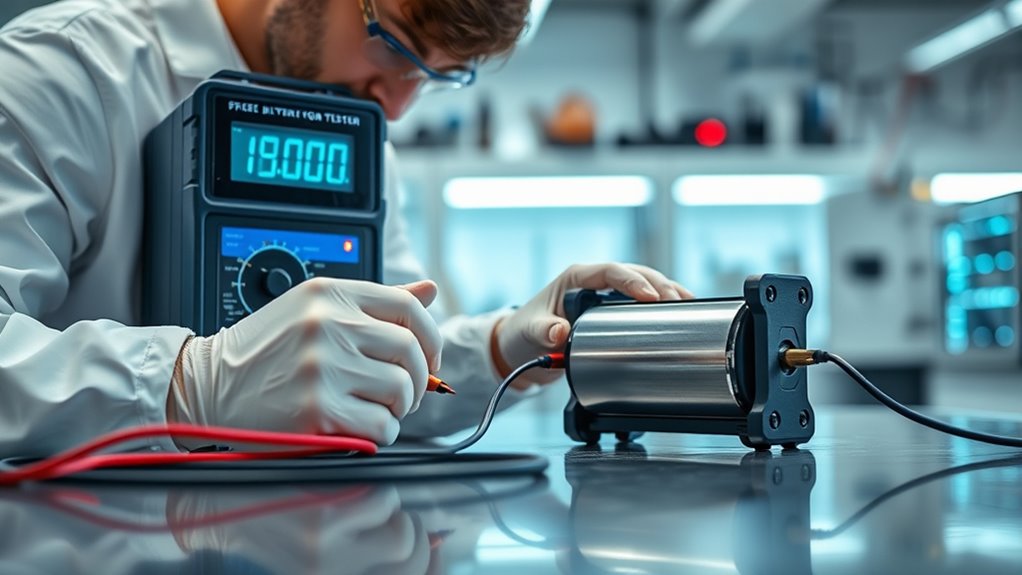

Testing the performance and durability of batteries is essential to guarantee they meet safety and efficiency standards. When you evaluate a battery’s condition, understanding its battery health becomes your top priority. Battery health indicates how well a battery can store and deliver power, which directly impacts device performance and longevity. To assess this, you rely on specialized testing equipment that provides accurate, real-time data about the battery’s internal state. Using the right tools ensures you can detect issues like capacity loss, internal resistance, or potential failure points before they lead to system failures.

Proper testing equipment is critical because it allows you to perform exhaustive evaluations quickly and reliably. You might use a battery analyzer or a multimeter to check voltage levels, but for a thorough assessment, more advanced devices are necessary. These tools can measure parameters such as internal resistance, charge retention, and cycle life. When you connect your testing equipment to a battery, you should follow standardized procedures to obtain consistent, comparable results. For example, performing a load test simulates real-world conditions, revealing how the battery performs under stress, which is essential for applications like electric vehicles or backup power systems.

Advanced testing tools like load tests ensure reliable, real-world battery performance assessments.

Monitoring battery health through regular testing helps prevent unexpected failures and prolongs the lifespan of the battery. As you conduct tests, pay attention to the data indicating capacity degradation—if the capacity drops below 80% of its original value, it’s a sign that replacement may be necessary. Internal resistance measurements are equally important; increased resistance can signal deterioration of the battery’s internal components, leading to reduced efficiency and potential overheating. Accurate data from your testing equipment enables you to make informed decisions about maintenance, repair, or replacement, ultimately saving money and preventing safety hazards.

In addition to initial testing, ongoing monitoring with appropriate testing methods keeps your batteries in ideal condition. For example, periodic capacity tests and resistance measurements can reveal trends indicating aging or damage. By establishing a routine testing schedule, you ensure that your batteries remain reliable and safe over time. Keep in mind that environmental factors like temperature and usage patterns influence battery health, so testing should be performed under controlled conditions whenever possible.

Frequently Asked Questions

How Often Should I Test My Vehicle Battery?

You should test your vehicle battery at least twice a year to monitor its health and guarantee ideal performance. Regular testing helps you spot issues early, extending the battery lifespan and preventing unexpected failures. If you frequently drive in extreme weather or use your vehicle often, consider testing more often. Maintaining a consistent testing frequency keeps your battery reliable and avoids costly repairs or replacements down the line.

Can I Test My Battery at Home Without Proper Tools?

Think of your battery as the heart of your car’s symphony. You can attempt DIY testing, but homemade tools often lack the precision needed to truly gauge health. While you might perform simple voltage checks with a multimeter, more complex diagnostics require proper equipment. Without proper tools, you risk missing subtle signs of weakness. For accurate results, it’s best to rely on professional testing or invest in quality diagnostic tools—your vehicle deserves the best care.

What Are Signs of a Failing Battery Besides Testing?

If your battery is failing, look for visual indicators like cracks or leaks and corrosion signs around the terminals. You might notice slow engine cranking, dim headlights, or electrical issues as well. These signs suggest the battery isn’t performing properly. Pay close attention to any unusual smells or swollen casings. Addressing these warning signs early can prevent your vehicle from getting stranded and help you decide when to replace the battery.

How Does Temperature Affect Battery Testing Results?

Temperature considerably impacts your battery testing accuracy because of its temperature sensitivity. When it’s too cold, your battery’s internal resistance rises, leading to lower voltage readings and potentially false failures. Conversely, high temperatures can cause overestimates of capacity but accelerate battery wear. To get accurate results, you should test batteries at standard room temperature, around 20-25°C, and avoid extreme conditions that skew your testing outcomes.

Are There Specific Testing Methods for Different Battery Types?

You might think one testing method fits all batteries, but different chemistries need tailored approaches. For example, lithium-ion batteries require specific testing equipment to accurately measure capacity and health, while lead-acid batteries need different procedures to check for sulfation or plate corrosion. Investigate how battery chemistry affects testing, and always use the right equipment to guarantee precise results. This way, you get reliable data for any battery type.

Conclusion

By mastering proper battery testing methods, you’ll open the secret to endless power and peak performance. Skip these steps, and your battery could fail at the worst possible moment—like during a life-or-death situation! Think of these techniques as your ultimate shield against unexpected power failures. With consistent testing, you’ll guarantee your battery never lets you down, turning you into a true power hero who’s always prepared. Don’t settle for less—test like a pro and dominate with reliable energy!