When choosing threadlockers, you’ll find they come in various types like medium-strength options for parts that need future service, and high-strength variants for critical components that require a permanent fit. These adhesives prevent fasteners from loosening due to vibration or stress, while also resisting corrosion and temperature fluctuations. Knowing which type fits your application is key to ensuring safety and longevity. Keep exploring to learn more about each threadlocker’s specific uses and advantages.

Key Takeaways

- Different threadlockers range from medium to high strength, chosen based on whether disassembly is needed later.

- Medium-strength threadlockers are ideal for components requiring future servicing, allowing easy removal.

- High-strength variants provide a permanent lock for critical fasteners in high-stress applications.

- Threadlockers offer corrosion resistance, protecting threads from rust and wear over time.

- They are widely used in automotive, aerospace, and machinery to prevent loosening due to vibration or thermal changes.

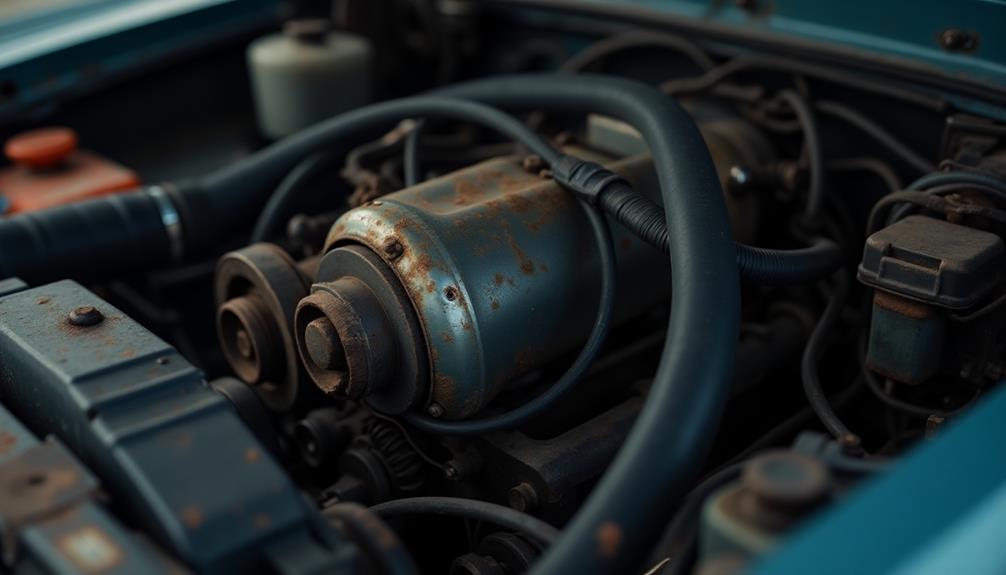

Threadlockers are crucial adhesives that prevent fasteners from loosening due to vibration or stress. When you’re working on machinery or equipment where stability is critical, using the right type of threadlocker can make a significant difference. For automotive repairs, threadlockers offer numerous benefits. They help maintain the integrity of engine components, suspension parts, and other fastened assemblies that experience constant movement and vibration. By applying a threadlocker, you reduce the risk of bolts backing out or becoming loose over time, which can cause serious safety issues or costly repairs. This added security also minimizes the need for frequent retightening, saving you time and effort during maintenance.

In the automotive world, choosing the appropriate threadlocker depends on the application’s demands. For instance, medium-strength options are ideal for parts that may need future service, allowing you to disassemble without damaging the fasteners. High-strength variants, on the other hand, are suited for critical components that require permanent locking, such as engine studs or transmission bolts. The benefits extend beyond just preventing loosening; threadlockers also provide corrosion resistance, protecting threads from rust and wear. This is especially advantageous in vehicles exposed to harsh environments, snow, or salt, where corrosion can weaken fastener connections over time. Additionally, threadlockers are designed to resist temperature fluctuations, ensuring secure fastening even in extreme heat or cold.

The applications of threadlockers aren’t limited to automotive repairs—they play an indispensable role in the aerospace industry. In aerospace, safety and reliability are paramount, and threadlockers serve as an essential part of the assembly process. They ensure that fasteners stay secure under extreme conditions, including high vibrations, rapid temperature changes, and stress during flight. Aerospace engineers rely on specialized threadlockers that meet strict standards for strength and chemical resistance. These adhesives provide a dependable seal, preventing fasteners from loosening or failing, which could have catastrophic consequences. Additionally, their ability to withstand harsh environmental factors makes them indispensable for aircraft maintenance and manufacturing, where every fastener needs to perform flawlessly over long periods.

Frequently Asked Questions

Can Threadlockers Be Removed After Curing?

Yes, you can remove threadlockers after curing. The removal methods depend on the type and the curing process, but usually, applying heat with a heat gun or torch softens the adhesive, making it easier to unscrew the fasteners. For more stubborn threadlockers, use specialized solvents or hand tools. Always follow safety precautions during removal, and consider the curing process to determine the best method for effective disassembly.

Are Threadlockers Suitable for High-Temperature Applications?

Yes, some threadlockers are suitable for high-temperature applications. You should look for high temperature adhesives designed specifically for this purpose, as they can withstand elevated heat without losing their bond. Additionally, if you’re working with plastics, opt for plastic safe sealants that won’t damage the material. These specialized options guarantee your threaded connections stay secure even under extreme heat, providing reliable performance in demanding environments.

How Long Does It Take for Threadlockers to Fully Cure?

You’ll find that threadlockers typically take about 24 hours to fully cure, but curing time can vary based on application factors like temperature, humidity, and the amount applied. To guarantee ideal bonding, make sure the surface is clean and dry before application. For faster results, you can use a heated environment or a thinner layer, but always follow the manufacturer’s recommendations to achieve a strong, durable bond.

Are There Environmentally Friendly or Low-Toxicity Threadlockers?

Yes, there are environmentally friendly, low-toxicity threadlockers available. You can look for biodegradable adhesives and non-toxic formulations that reduce environmental impact while maintaining effective locking properties. These options are designed to be safer for you and the environment, often made with fewer harmful chemicals. When choosing a threadlocker, check labels for eco-friendly certifications or mentions of biodegradable and non-toxic ingredients to guarantee you’re making a responsible choice.

Can Threadlockers Be Used on Plastic Components?

Using threadlockers on plastic components is definitely doable, but you need to choose the right type to guarantee plastic compatibility. Some threadlockers are specially formulated for plastics, offering strong threadlocker adhesion without damaging the material. Always check the product label for plastic compatibility, and apply sparingly. Using the wrong threadlocker can cause the plastic to weaken or crack, turning your project into a fragile masterpiece.

Conclusion

Understanding threadlocker types helps you choose the right adhesive for your needs, ensuring secure and long-lasting connections. Did you know that over 70% of fastener failures are due to vibration or loosening? By selecting the appropriate threadlocker, you can prevent costly repairs and improve safety. So, next time you work on a project, remember that the right threadlocker isn’t just a quick fix—it’s a smart investment in durability and peace of mind.