A bad ground connection occurs when the electrical ground isn’t secure or becomes corroded, causing increased resistance and interrupting the safe path for current. This can lead to system malfunctions, electric shocks, or equipment damage, as the grounding isn’t effectively redirecting excess current during faults. Recognizing how corrosion or loose connections impact grounding is key. If you want to understand more about how to identify and fix these issues, keep exploring how proper grounding protects your system.

Key Takeaways

- Bad ground connections disrupt circuit continuity, increasing resistance and preventing proper current flow.

- Corrosion at grounding points can insulate connections, weakening the grounding path.

- Loose or broken ground wires compromise safety, risking electric shocks and equipment damage.

- Poor grounding leads to faults not being properly redirected, causing system malfunctions.

- Regular inspection and maintenance are essential to prevent and fix bad ground connections.

Understanding ground connections is essential for ensuring electrical safety and proper system operation. When a ground connection isn’t solid, it can cause a range of problems, from safety hazards to equipment malfunctions. One key aspect to contemplate is circuit continuity. A proper ground connection provides a continuous path for electrical current to flow back to the ground, which is critical for protecting you and your equipment. If the circuit isn’t continuous, maybe due to loose connections or broken wires, electrical faults can occur. This interruption can prevent the system from safely redirecting excess current during a fault, increasing the risk of electric shock or equipment damage. Ensuring circuit continuity means inspecting and maintaining ground connections regularly, especially in environments where vibrations or physical stress might loosen connections over time. Regular maintenance and testing can help identify issues before they lead to failures or hazards.

Corrosion effects play a crucial role in weakening ground connections. Over time, exposure to moisture, salt, or chemicals can cause corrosion on grounding conductors and terminals. When corrosion develops, it acts like an insulator, impeding the flow of current and compromising circuit continuity. You might notice signs like rust, discoloration, or a build-up of white or greenish deposits around connection points. These are clear indicators that your ground connection is deteriorating. If left unchecked, corrosion can considerably increase resistance in the grounding path, making it less effective at safely directing fault currents away from your system. This not only jeopardizes safety but can also lead to unpredictable system behavior, such as unexpected tripping or electrical noise. Corrosion resistance is vital for maintaining a reliable grounding system over time.

To prevent corrosion effects from undermining your ground connections, regular inspections are crucial. Use tools like a multimeter to test the integrity of your grounding system periodically. Tighten any loose connections and replace corroded components promptly. Applying anti-corrosion coatings or using corrosion-resistant materials can also extend the lifespan of ground connections, especially in harsh environments. Remember, a clean, secure, and corrosion-free ground connection guarantees better circuit continuity, ensuring your system functions reliably and safely. Neglecting these maintenance steps can result in increased resistance, faulty operation, and even dangerous situations. In sum, taking proactive measures to maintain solid ground connections not only safeguards your equipment but also protects you and others from potential electrical hazards. Proper grounding is a simple yet critical aspect of electrical safety that demands your attention and regular upkeep.

Frequently Asked Questions

How Do I Identify a Bad Ground Connection Visually?

You can identify a bad ground connection visually by inspecting for ground corrosion, which appears as greenish or whitish deposits on metal parts. Look for loose wiring, frayed wires, or disconnected grounds, as these can cause poor connections. Check for any signs of rust or corrosion around grounding points, and guarantee all bolts and connectors are tight and secure. If anything looks damaged or suspicious, it’s likely affecting your ground connection.

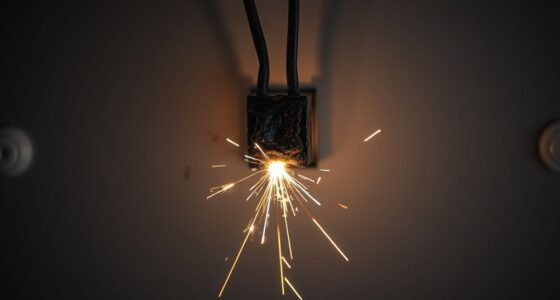

Can a Bad Ground Connection Cause Electrical Fires?

Yes, a bad ground connection can cause electrical fires, risking lives and property. When ground faults occur, ground fault detection systems can often prevent disasters by alerting you early, but only if electrical safety standards are adhered to. Ignoring poor grounding might lead to overheating and sparks, making fire a real danger. Always verify your wiring meets safety standards to protect your home and loved ones from preventable fires.

What Tools Are Best for Testing Ground Connections?

You should use a ground tester or a voltage meter to test ground connections effectively. A ground tester quickly checks for proper grounding by indicating continuity or resistance, while a voltage meter measures voltage differences, helping identify poor connections. Always guarantee your tools are calibrated and suitable for electrical testing. By using these tools, you can accurately determine if your ground connection is secure, preventing potential electrical issues.

How Often Should Ground Connections Be Inspected?

Like tuning a vintage radio, you should inspect your ground connections regularly—at least once a year or after severe weather. Check for signs of ground wire corrosion and verify your grounding system upgrades are intact. Frequent inspections help catch issues early, preventing electrical failures or safety hazards. By staying proactive, you keep your system reliable and safe, avoiding costly repairs down the line.

Are There Specific Signs Indicative of Hidden Ground Faults?

Yes, there are specific signs of hidden ground faults. You might notice ground fault symptoms like frequent tripping of circuit breakers, flickering lights, or tingling shocks when touching appliances. These issues often point to hidden wiring issues or poor ground connections. If you observe these signs, it’s crucial to inspect and fix the problem promptly to prevent electrical hazards and guarantee your system’s safety.

Conclusion

Understanding bad ground connections is like finding a loose screw in a machine—you might not notice it at first, but it can cause big problems down the line. By checking and maintaining solid ground connections, you keep your electrical system running smoothly and safely. Remember, a good ground is the foundation of reliable electrical performance, so don’t overlook it. Keep everything tight and secure, just like a well-built bridge supporting a busy road.