High-voltage service disconnects are crucial safety devices that isolate electrical systems from power sources, protecting maintenance personnel and preventing electrical hazards. They act as essential barriers, reducing the risk of arc flashes and equipment damage. Proper use and regular testing ensure they function correctly when needed. If you want to understand how insulation testing enhances safety and supports disconnect reliability, keep exploring the essential role these devices play in electrical safety.

Key Takeaways

- High-voltage service disconnects serve as critical safety devices to isolate electrical systems from power sources.

- Proper inspection and maintenance of disconnects prevent electrical faults and enhance system safety.

- Insulation testing verifies the integrity of components within high-voltage disconnects, reducing arc flash risks.

- Adhering to industry standards ensures disconnects function reliably and protect personnel from electrical hazards.

- Upgrading or replacing aging disconnects maintains system safety and complies with evolving safety regulations.

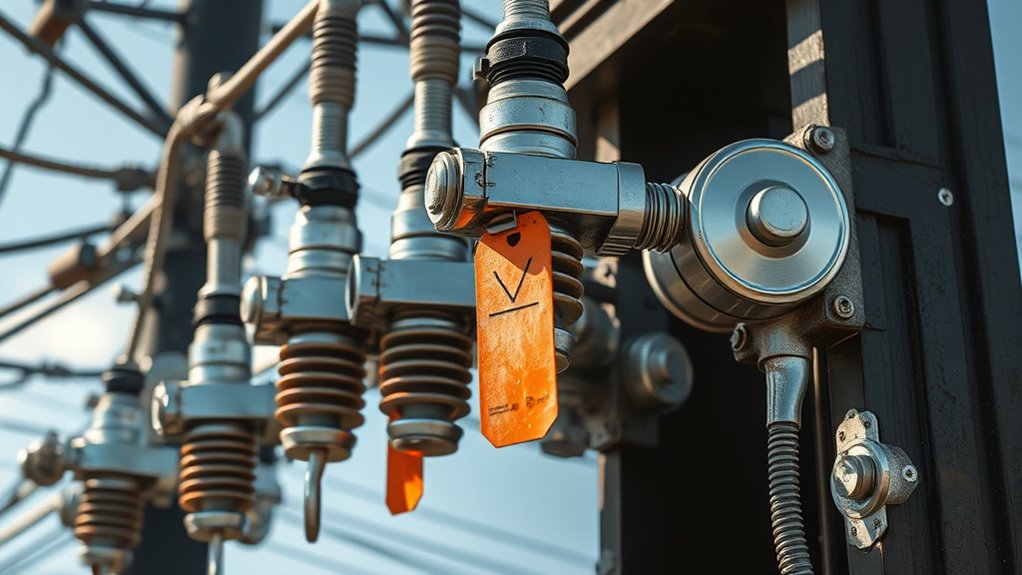

High-voltage service disconnects are essential safety devices that safely isolate electrical systems from the power source. When working with high-voltage equipment, ensuring proper disconnection is critical to preventing accidents and protecting personnel. A key part of maintaining these disconnects involves regular insulation testing, which verifies the integrity of the insulation surrounding electrical components. By conducting insulation testing, you can detect deterioration, moisture ingress, or other issues that could compromise safety. This proactive approach helps prevent faults that might lead to dangerous arc flashes, which are intense bursts of electrical energy capable of causing severe injuries or fatalities. Proper insulation testing reduces the likelihood of arc flash incidents by confirming that the disconnects and associated equipment remain in good condition, capable of handling the voltage levels safely.

You need to understand that high-voltage disconnects aren’t just simple switches; they’re vital safety barriers that, when properly maintained, minimize the risk of electrical hazards. Regular inspection and testing are essential parts of a comprehensive safety program. During testing, you check for insulation resistance, ensuring that no unintended electrical paths exist that could cause short circuits or arc flashes when the disconnect is operated. If insulation integrity is compromised, you should replace or repair affected parts before re-energizing the system. This step is crucial because arc flash safety measures rely heavily on the integrity of the entire electrical system. When insulation is intact, it mitigates the chances of accidental arcs, especially during switching operations or fault conditions. Recent advancements in AI-driven testing techniques enhance the accuracy and efficiency of insulation assessments, further supporting safety protocols.

Additionally, understanding the importance of insulation testing helps you appreciate how it supports overall arc flash safety. Arc flashes occur when electrical energy is suddenly released through an arc, often caused by equipment failure or improper maintenance. By verifying insulation quality, you reduce the risk of such incidents, creating a safer environment for everyone working around high-voltage equipment. Properly maintained disconnects, combined with routine insulation testing, form a critical line of defense against arc flash hazards. You should always follow industry standards and best practices for testing procedures, ensuring that your safety protocols are up-to-date and effective.

Frequently Asked Questions

What Are the Maintenance Requirements for High-Voltage Disconnects?

You should perform regular preventive maintenance on high-voltage disconnects, including inspecting for signs of wear or damage. Component testing is essential to guarantee proper operation, checking contacts, insulation, and control mechanisms. Clean the components to prevent dirt or corrosion from affecting performance. Schedule these tasks based on manufacturer recommendations and operational conditions, and always follow safety protocols during maintenance to prevent electrical hazards.

How Do I Troubleshoot Issues With High-Voltage Disconnects?

Did you know that improper troubleshooting causes 30% of high-voltage disconnect failures? To troubleshoot, start by inspecting for fault detection signals and checking for contact wear or corrosion. Use a multimeter to verify voltage levels and confirm the disconnect operates correctly. If you find abnormal readings or signs of wear, replace or repair components promptly. Regular testing helps prevent unexpected failures and ensures reliable operation.

What Safety Precautions Should Be Taken During Installation?

You should always wear personal protective equipment, like insulated gloves and safety glasses, when installing high-voltage disconnects. Make sure you’ve undergone proper safety training to understand the risks and procedures. Before starting, double-check that the power is fully disconnected and locked out. Follow all manufacturer instructions and local electrical codes. Never rush the process, and stay alert to prevent accidents or injuries during installation.

Are There Different Types of High-Voltage Disconnects?

High-voltage disconnects are like tools in a toolbox—various types suit different needs. You’ll find air, oil, and vacuum circuit breakers, each with unique advantages. When comparing types, consider installation standards and safety features. Proper selection guarantees reliable operation and safety. Always follow manufacturer guidelines and electrical codes to match the disconnect type to your system requirements, ensuring safe, efficient high-voltage service management.

How Often Should High-Voltage Disconnects Be Inspected or Replaced?

You should inspect high-voltage disconnects annually to guarantee proper corrosion prevention and to check for signs of wear. Replace them if you notice corrosion, thermal expansion damage, or loose connections. Regular inspections help prevent failures caused by thermal expansion stresses or corrosion buildup. Keeping these disconnects well-maintained ensures safe, reliable operation, reducing the risk of outages or electrical hazards. Schedule professional assessments to maintain peak performance.

Conclusion

Just like Icarus reaching too close to the sun, pushing high-voltage limits can lead to disaster. Always respect the power of high-voltage disconnects, and never take shortcuts with safety. By understanding and properly managing these systems, you prevent sparks from turning into flames. Remember, in the world of electricity, wisdom is your best shield—so stay vigilant, follow procedures, and keep yourself grounded. Safety isn’t just a rule; it’s your guiding light in the dark.